Powdered materials additives flash drying

Application clients:Foshan nanhai Wan Xing materials technology co., LTD

Classification of the project:Building materials additives engineering industry

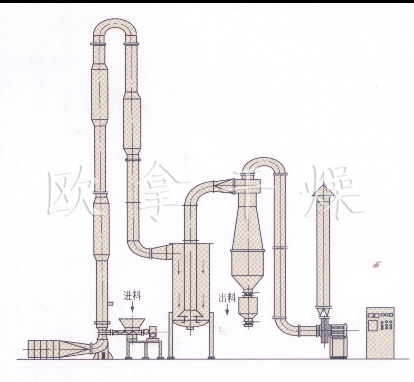

Choose products:SXG series of spin flash dryer

Project description:

The powdery additive for building materialsSpin flash dryerHas strong pertinence, practicality, high energy efficiency.We are production equipment for the user, according to the characteristics of dry products required, the user process requirement, combined with decades of experience to the most suitable quality for the user design and production of the best drying equipment.

Description of equipment:

Flash dryer is mainly composed of ventilation system, heating system, charging system, dry host, receiving for dust removal system, exhaust system, control system, etc.Work, wet material by a spiral feeder into the drying chamber, the material in the drying chamber and high-speed rotating hot air meet, fine powder material by hot air to the drying chamber with the top mobile, can't take away the material in the bottom of the drying chamber, was broken at the bottom of the crushing device, the material being spread quickly, material contact area increased rapidly with hot air.Under the action of centrifugal force (at the top of the grading device), dry degree and a certain fineness of products was blown out of grading device, material in the process to get fast drying.

Equipment characteristics:

Flash drying machine has high technology content, high standardization, environmental protection, security, low consumption, simple maintenance etc, in the design of the structure:

(1) dry bottom taper structure, make the dry gas flow area gradually expand from bottom to top, the bottom of the air flow is opposite bigger, the upper air flow is relatively small, so as to ensure the large particles in the fluidized state of bottom at the same time, the upper part of the small particles in the fluidized state, and make the hot air along the vertebral rotation, improve the wind speed at the bottom, reduce the length of the stirring shaft bracket part, increase the safety and reliability of operation;Can make the bearing on the outside, effectively prevent the bearings work in high temperature, so as to prolong the service life of the bearing.

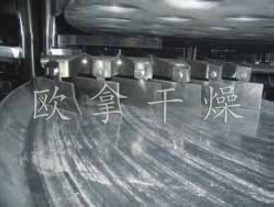

(2) stirring tooth set on scraper, material in the stirring tooth grinding at the same time, and was put to the wall, the stick on the wall, if not timely scraping, serious when they make the equipment vibration, even result in blender choke up did not turn.Stirring tooth set on scraper, can in time peeling stuck to the machine wall material, avoid sticky wall.

(3) the stirring shaft revolutions are controlled by stepless speed regulating motor.According to the product particle size requirement to select different rotating speed, the faster the stirring shaft speed, the smaller of the particle size of the product is.

(4) upper dryer set classifier, by changing the hole diameter and the height of the grading period of classifier, and then change the air velocity, left dryer control of particle size and quantity, final moisture content and material in the drying period of time.

(5) of the feeder screw conveyor revolution by inorganic speed motor control.According to the material properties and drying technological parameters control the feeding speed.

6 equipment structure is compact, cover an area of an area small, drying, crushing, grading, is hydrocyclone technology, streaming technology, spray technology and the organic combination of convection technology, drying after no longer need to crushing, screening, simplify the production process, saving power and equipment costs.

Products center

Dryer Series

- Flash dryer series

- Vacuum dryer series

- Belt dryer series

- Special oven series

- Air dryer series

- Fluidized bed dryer series

- Boiling dryer series

- Spray dryer series

- Sludge dryer series

- Disc dryer series

Mixer Series

Grinder Series

Screening series

Granulator series

Heat source series

Auxiliary Series

Contact:Wu Yaohong (General Manager)

Phone:13861037227

Tel:0519-88908708

Fax:0519-88910209

Email:office@ounadry.com

Address:Chajiawan , Jiao xi zhen, Changzhou, Jiangsu province ,China